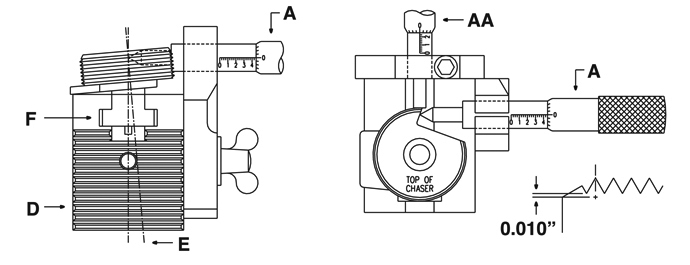

The gauge is designed so the chaser block (with chaser mounted on it) is fitted in the gauge slots.

Adjust micrometer holding brackets on the side and end of the gauge to a height which permits that flat spindle of barrel AA to contact the chaser thread groves about two or three threads from the top of the chaser, and the point of the spindle of barrel A to touch the chaser face approximately in line with the crest of the first full thread. |

|

Set micrometer barrel AA to read single thread depth plus .010”. Thus, when chaser is located against the flat spindle of barrel AA, the spindle point of micrometer barrel A contacts the chaser face at a point .010” below the root diameter of the thread. This distance below the root diameter may be increased if the operator desires, depending on thread pitch or nature of grind. (See chart “AA” reading for actual settings) |