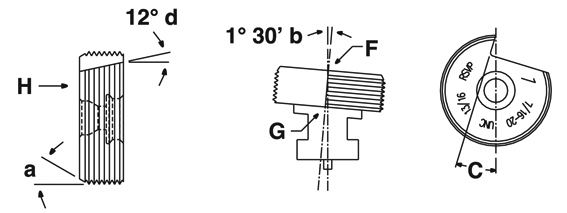

Regrinding and setting taper thread chasers and blocks for dieheads varies only in respect of the fixture base setting which controls the face angle.

Whereas the standard setting of 6 degrees produces a face angle of 1 degree 30 minutes on chaser, the base setting for taper thread chasers must be found by experiment.

These particular chasers when ground and set will have no face angle, but will be square with the base of the chaser block.

To achieve this, alter base setting from 6 degrees to 5 degrees. Grind two chasers to normal 22 degrees hook angle. Stand these on a flat surface and bring the two ground face angles in contact with each other. These two faces should touch from top to bottom in their length. |

|

When correct base reading has thus been obtained, the chasers and blocks will then be ground and set in the normal manner, except that it is necessary to lower the bracket carrying micrometer A to the same level as micrometer AA. This will enable micrometer A to contact the chaser face at the depth of the thread plus 0.010”.

Finally, we find it advisable to grind the chasers to a slightly higher micrometer reading than normal.

Where hook angles other than 22 degrees are required, the base readings, as shown above would vary and have to be found by experiment |